Hydrogen in the home is closer than you think

Delivering renewable hydrogen via existing distribution networks can allow customers to continue enjoying the benefits of gas without the greenhouse gas emissions.

Blending 20 per cent hydrogen underway.

The HyDeploy[1] project in the UK is a pioneering hydrogen project designed to help reduce UK CO2 emissions and reach the Government’s net zero target for 2050.

The first phase of HyDeploy is complete. This phase developed a safety case to provide a 20 per cent hydrogen blend to a dedicated gas network at Keele University. The safety case collected assets from the field and tested their performance with hydrogen blends. More than 200 assets were collected from across the UK. The general conclusion was that these assets performed at the same level with hydrogen blends as expected for natural gas. This resulted in an exemption being granted allowing blending at Keele University to commence. The trial at the university demonstrated that a 20 per cent blend can be safely delivered[2]. The project also showed that customers didn’t notice any difference when using the hydrogen blend and that existing cooking or heating appliances could continue to be used.

The next phase is delivering a 20 per cent blend to a town in the North of England. This has been ongoing since August 2021 in Winlaton, which comprises 668 homes, a church, primary school and several small businesses. This trial will continue until mid-2022.

A 20 per cent hydrogen blend is suitable for UK appliances as the UK Gas Appliance Directive[3] has required all appliances be tested on a blend of 23 per cent hydrogen before they can be approved for market.

In Australia, gas distribution networks are continuing to complete testing with Future Fuels CRC for network materials and components on hydrogen blends and 100 per cent hydrogen.In Victoria, there are no constraints to gas networks providing a blend of up to 20 per cent hydrogen.

Testing of appliances in Australia has been completed on up to 10 per cent hydrogen and has found that these appliances can safely continue to perform at this level. Ongoing research is testing whether Australian appliances can continue to operate safely with a 20 per cent hydrogen blend, like the UK, or higher. Separate tests are needed compared to those in the UK as the natural gas specification and operating conditions of Australian networks differ to those in the UK. Network readiness to deliver 100 per cent hydrogen.

Gas distribution businesses in Australia have been converting their cast iron mains to plastic alternatives. The purpose of these replacements is to improve the safety of the network by reducing leakage and to increase the carrying capacity of the networks.

The original networks were used to deliver towns gas, which contained up to 60 per cent hydrogen, albeit at a lower pressure than present gas networks.

Replacing these pipes with modern alternatives will allow hydrogen to be safely delivered through the gas networks. The current proposals being assessed by the Australian Energy Regulator (AER) for Victoria’s gas distribution networks will see all the network conversions being completed between 2022 and 2030. These plans still need approval by the AER.

Additionally, Future Fuels CRC has an active research program with a high level of engagement and support from the industry to investigate whether 100 per cent hydrogen impacts the performance of plastic distribution networks[4]. Early testing results have shown minor changes to some network materials but at a level unlikely to alter the overall risk profile when using hydrogen instead of gas. Moreover, the current safety controls in operating and maintaining gas networks can easily be adjusted to respond to changes in materials. For example, some (not all) elastomers used as seals in valves and joints may deteriorate faster with 100 per cent hydrogen compared to natural gas. Networks have a regular replacement program for these elastomers and they would be replaced with better performing variants before hydrogen injection, ensuring that a network delivering 100 per cent hydrogen remains as safe as it is today with natural gas.

Modern plastic gas networks are already installed in many key growth areas in Victoria, for example Cranbourne or Wollert, which makes these areas ready for 100 per cent hydrogen and ideal candidates for a demonstration of a hydrogen home and an opportunity for Australia’s first hydrogen suburb by 2030.

When can we get hydrogen appliances?

Existing gas appliances are only suitable to take a blend of hydrogen (up to 10 or 20 per cent as mentioned above) and modifications to appliances will be needed for them to operate safely and efficiently on 100 per cent hydrogen.

The Hy4Heat program in the UK has developed and certified household appliances that work on 100 per cent hydrogen. This includes cooktops, space heaters, boilers, hot water heaters, meters, as well as gas appliance components. Leaflets from the manufacturers for these range of appliances have been produced. https://www.hy4heat.info/wp4

The cooktop flame is a bright orange colour and cut off devices have been added for increased safety.

Figure 1: Bright coloured orange flames from using 100 per cent hydrogen on cooktops (Source: HyGrove)

These appliances and components have been certified and are being demonstrated in the UK’s hydrogen home – HyGrove[5]. These appliances were also showcased at the recent COP26 meeting in Glasgow in late 2021[6].

The UK’s four largest gas appliance manufacturers, which have developed the certified gas appliances, have committed to produce hydrogen-ready boilers at the same price as their natural gas systems today[7].

Figure 2: Commitment of boiler manufacturers to delivers hydrogen ready boilers at the same price as their natural gas systems today.

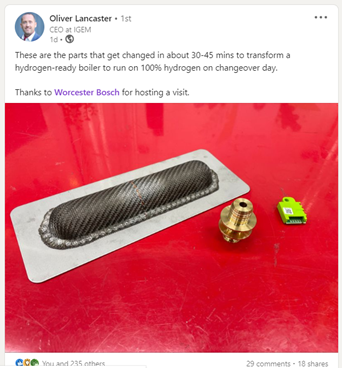

To minimise the impact on conversion to hydrogen, ENA (UK)[8] is supporting an approach to mandate hydrogen-ready boilers from 2025. The intention is to replace gas boilers at the end of their life with a new hydrogen-ready equivalent that can easily be converted to hydrogen once networks are fully converted to hydrogen. A recent LinkedIn post showed that the conversion required only three parts and was completed in 30 to 45 minutes.

Figure 3: Parts replaced to transform a hydrogen-ready boiler to a 100% hydrogen boiler (Source: LinkedIn[9])

Mandating hydrogen-ready boilers before a conversion allows the stock of appliances to be partially replaced with hydrogen-ready ones and minimises the total number of boilers that need to be upgraded when the network converts to 100 per cent hydrogen. This minimises disruptions and costs of the conversion.

Australia is not as well advanced as the UK in developing appliances dedicated to the Australian market, but we are making strides There are several hydrogen BBQs available in Australia[10] used to demonstrate the role of hydrogen. Australia’s gas appliance manufacturers are actively engaged in the appliance research program[11] at Future Fuels CRC and are also independently pursuing the development of hydrogen appliances for the domestic market. International collaboration with UK manufacturers can accelerate the development and certification of hydrogen appliances in Australia.

Summary

Hydrogen delivered by your gas network is not some far away fantasy:

- Hydrogen blending is underway in Australia.

- Gas networks in Australia will be able to deliver 100 per cent hydrogen safely.

- Hydrogen appliances have been developed and certified overseas.

The fastest pathway to net zero includes the decarbonisation of gas and delivering hydrogen into our gas networks will help enable this. This will ensure we retain diversity of energy supply and customer choice, while keeping costs as low as possible.

[1] https://hydeploy.co.uk/

[2] https://www.keele.ac.uk/sustainable-futures/ourchallengethemes/providingcleanenergyreducingcarbonemissions/hydeploy/

[3] https://hydeploy.co.uk/winlaton/

[4] https://www.futurefuelscrc.com/program_area/material-properties-and-performance-rp3-1/

[5] https://www.northerngasnetworks.co.uk/2021/07/15/first-hydrogen-homes-open-to-the-public/ or https://www.youtube.com/watch?v=4ciu4qiVaDo

[6] https://www.hy4heat.info/wp8

[7] Energy & Utilities Alliance (2021), The Upfront Cost of Decarbonising Your Home, available from: https://eua.org.uk/resources/residential-heat-the-upfront-cost-of-decarbonising-your-home/

[8] https://www.energynetworks.org/newsroom/why-were-backing-mandating-hydrogen-ready-boilers-for-homes

[9] https://www.linkedin.com/posts/gasworksollie_these-are-the-parts-that-get-changed-in-about-activity-6919274607757692928-lku5?utm_source=linkedin_share&utm_medium=member_desktop_web

[10] For example: https://www.australiangasnetworks.com.au/news-and-articles/life/hydrogen-bbq-callum-hann-grilled-lamb

[11] https://www.futurefuelscrc.com/program_area/compatibility-of-end-user-equipment-with-future-fuels-rp1-4/