Money talks! What’s needed to decarbonise using hydrogen

Hydrogen is a versatile, clean and safe energy carrier that can be used in many applications. Industry sees hydrogen as a key enabler in transitioning towards decarbonising large parts of the economy. So, what’s needed to ensure hydrogen plays a key role in our nation’s decarbonisation journey?

The industry’s position on hydrogen is clear: it is a key enabler in transitioning towards decarbonising large parts of the economy. The Hydrogen Council – a partnership of 13 major international[1] energy and transport businesses – was formed in 2017 to underpin and leverage hydrogen’s role. The Council notes:

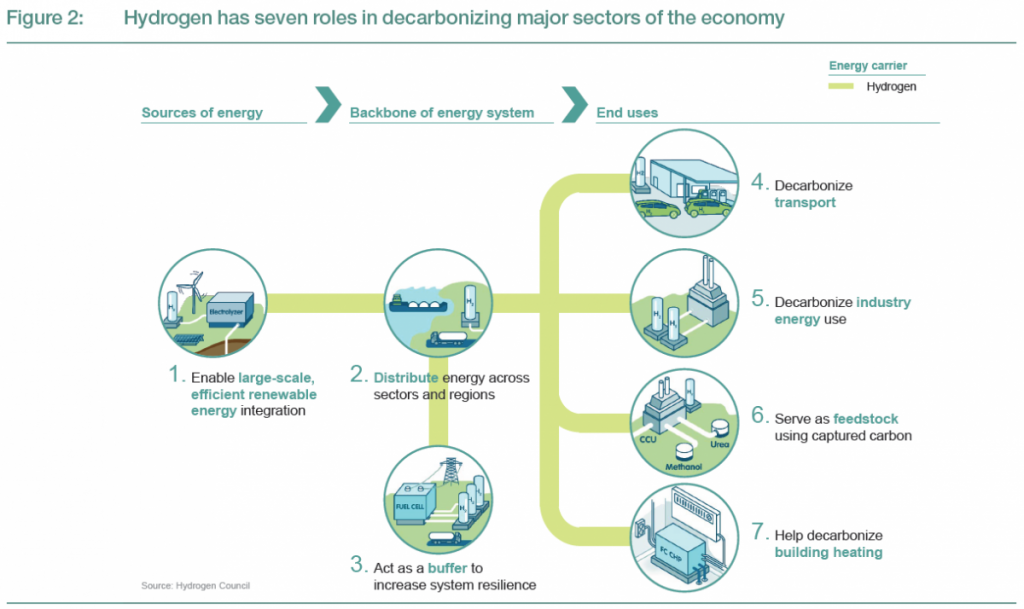

Hydrogen is a versatile, clean and safe energy carrier that can be used as fuel for power or industry as feedstock. It can be produced from (renewable) electricity and from carbon-abated fossil fuels. It produces zero emissions at point of use. It can be stored and transported at high energy density in liquid or gaseous form. It can be combusted or used in fuel cells to generate heat and electricity.

The seven incarnations of hydrogen are illustrated in the figure below. This includes balancing and buffering the electricity system (3), its use in transport (4) and decarbonising heat in buildings (7). Adopting these applications of hydrogen will help decarbonise Australia’s economy and stabilise our energy system.

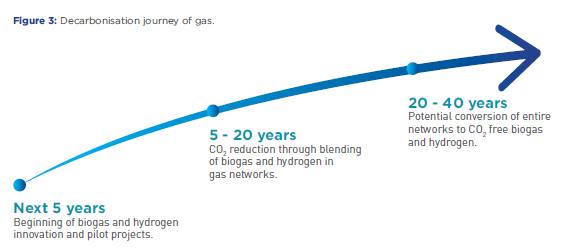

However, to date, our nation’s journey towards a clean energy future has primarily focused on decarbonising the electricity network, which accounts for about 30 to 35 per cent of Australia’s total energy usage. While gas is comparably low emission, its extensive use in homes, businesses and industry, and as transport fuel, makes decarbonising gas an important consideration to help meet our Paris agreement climate change obligations. To this end, gas distribution businesses, policy makers and regulators are supportive of decarbonising our gas networks using hydrogen technology. This is a long-term commitment involving the following milestones:

- 0 to 5 years: pilot and demonstration projects for learning and engagement

- 5 to 20 years: CO2 reduction through blending of low-carbon gas

- 20 to 40 years: potential large scale conversion of entire networks.

The South Australian (SA) Government’s Renewable Technology Fund[2] is supporting three major projects aimed at demonstrating the use of hydrogen technology to decarbonise a gas network.

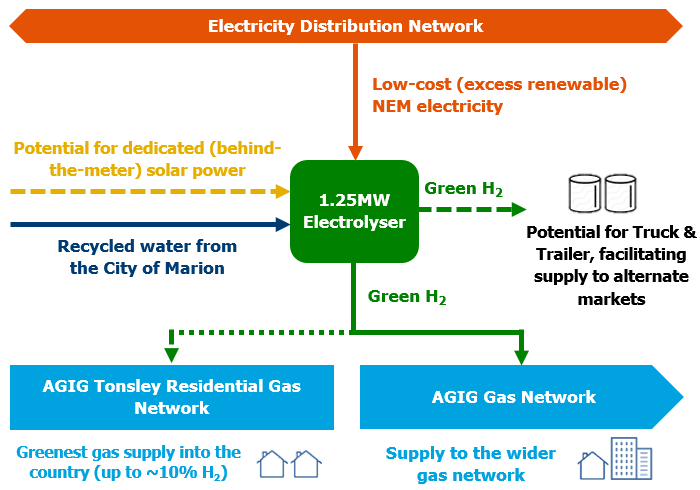

One of these projects is led by the Adelaide-based Australian Gas Infrastructure Group (AGIG). The SA Government is providing $4.9 million towards the $11.4 million demonstration plant. The project will demonstrate the production of hydrogen from renewable energy and recycled water and the utilisation of that hydrogen in the gas network.

The core project will use a 1.25 MW PEM[3] electrolyser based at the Tonsley Innovation District in Adelaide. TAFE SA offers its plumbing courses at this location, providing a unique opportunity for cross learning to upskill the plumbing sector in the use of hydrogen.

Hydrogen will be injected in the Tonsley Innovation District gas network, where up to 10 per cent of the gas could be replaced by hydrogen, and smaller amounts may also be injected across the broader gas network.

The project has far-reaching potential to shore up the National Electricity Market (NEM) by investigating how electrolysers can support network stability. The project will test the flexibility and response of the electrolyser to soak up excess renewable energy, demonstrating the buffer role shown in the Hydrogen Council image above. It is hoped this will provide a better understanding of how gas infrastructure can be used to store surplus renewable generated energy (in the form of hydrogen) that can then be imported directly in the gas network or used to generate electricity through a turbine during periods of peak demand.

Linking electricity and gas networks through hydrogen

Rooftop solar PV generates most electricity during the day when the demand is lowest. This excess renewable electricity could be used to produce hydrogen, which could then be stored in the gas network. In the early evening, when the sun goes down and air conditioning use increases, the hydrogen could be used directly in the home to power a gas-fired air conditioner, or used for electricity generation to provide power for traditional air conditioners. This process links the gas and electricity networks and makes optimum use of existing infrastructure, providing an alternative pathway for storing energy.

The project has the potential for a truck and trailer facility that would allow renewable hydrogen to be utilised in other sectors and supply alternate markets. For example, the hydrogen could be used for refuelling vehicles or a local bus fleet. It could also be used by industry as a potential green energy source.

The project is scalable so that beyond the demonstration stage, it could be scaled up by adding additional electrolysers through modular commercial expansion.

The current commercial size of electrolysers is about 1 MW. However, Siemens is commissioning a 10MW unit in Austria in late 2018.The technology’s storage capacity is developing rapidly, increasing by an order of magnitude every five years. It is expected that by the mid-2020s, the commercially available size of an electrolyser will be about 100 MW and that costs will have reduced by more than 40 per cent.

This future landscape will open up vast opportunities for injection of hydrogen at small concentrations across the network. Conversion to 100 per cent hydrogen networks could be used domestically, for example, to refuel vehicles, and also, export the hydrogen to power hungry markets such as Japan and Korea.

AGIG is currently completing the detailed front end engineering and design work for the project. It is expected that procurement of long-lead items will be attained later this year to enable site works to start mid-2019. Commercial operation of the project is expected to start mid-2020 and the project will have a five-year operating life.

There are a range of other projects demonstrating the commercial viability of hydrogen. Project proposals in other regions and by vehicle manufacturers are also in development. In the short term, better focussed government policy should enable the demonstration of the technology, as well as ongoing research and development support for other low emission innovation, such as solar thermal. This, in addition to the establishment of flexible, transparent regulatory frameworks will give the gas industry its best chance to successfully decarbonise.

[1] These businesses are: Air Liquide, Alstom, AngloAmerican, BMW Group, Daimler, Engie, Honda, Hyundai, Kawasaki, Shell, The Linde Group, Total and Toyota.

[2] http://ourenergyplan.sa.gov.au/hydrogen

[3] A proton exchange membrane (PEM) electrolyser is one type of electrolyser that is commercially available. Other types include solid oxide or anion exchange processes.